A spring is a very good thing and used in a number of goods. One of the best features of the spring is that it can come back to its original place no matter how much you stretch it or mold it. The resiliency of the spring depends on the kind of material that is used to make it. The material can vary according to the strength that it there in it and the cost that will be incurred and availability of the material, resistance of the corrosion, permeability of the magnet and the conductivity of the electricity. Let us now have a look at a list of few things that are made with the use of the spring material:

- Cold drawn and patent wire

- Cold rolled low-alloy steel and cold drawn

- Harden able spring steel

- Stainless spring steel

- Oil tempered spring wire and binate hardened strip

- Stainless spring steel with extremely good corrosion properties

- Stainless non-magnetic steel

- Stainless spring steel for higher temperatures

- Alloys for medical applications

- Anti-magnetic acid-resistant spring steel etc

- Copper alloys

- Titanium alloys

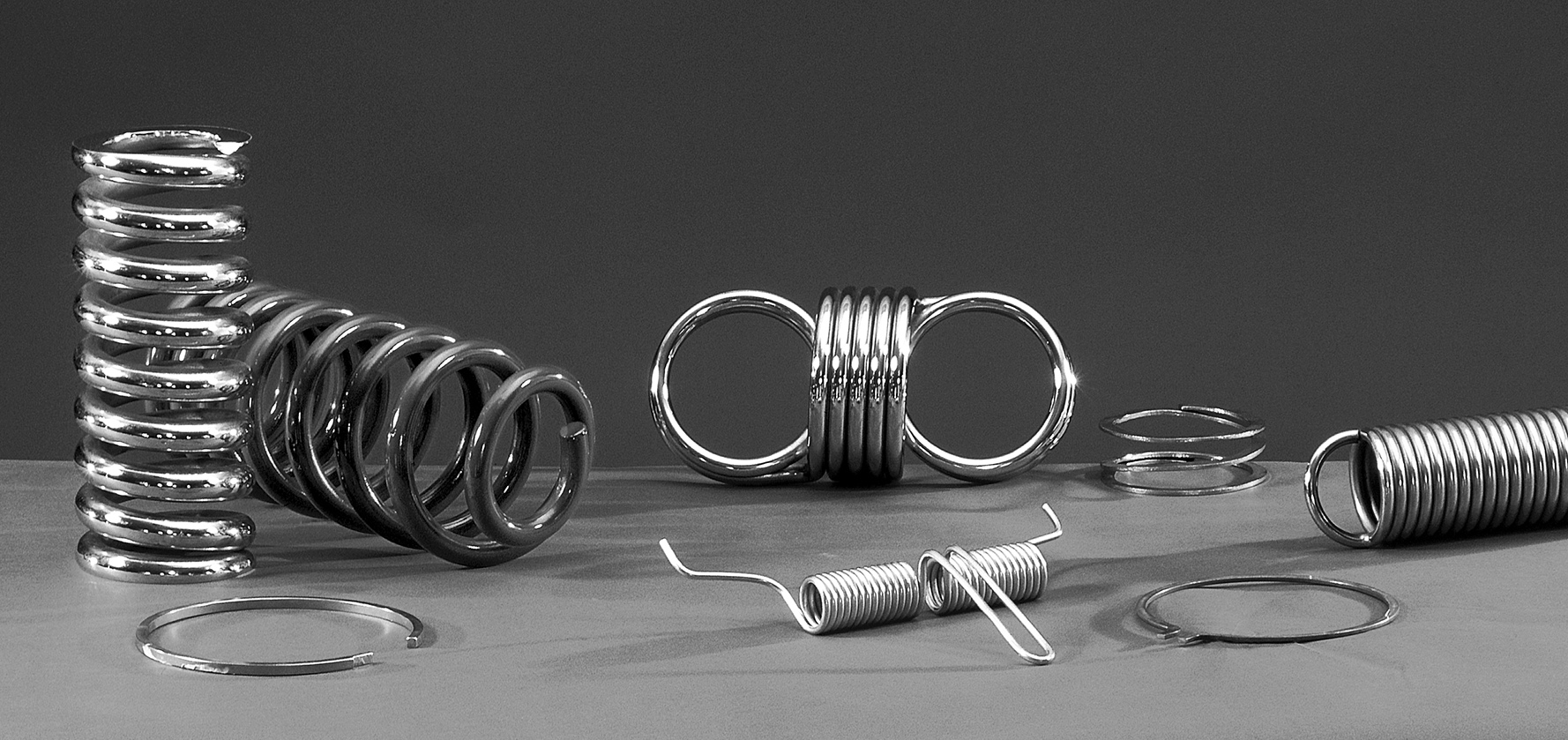

There are a number of items that we use daily that are made with the use of the spring. There are sofas, mattresses, cycle parts etc. These are a few common things that we all use daily and there is a use of spring in these things. Let us now have a look at the different variety of spring that is available for use. Each of the categories has different features and uses by the stainless steel spring manufacturers:

- High carbon steel spring- We shall study this material by dividing it in twelve different categories that are nominal analysis, minimum tensile strength, modules of elasticity, psi*103, design stress minimum, modulus in torsion, maximum temperature in F. and maximum temperature in C., rock well hardness and the methods with the help of which it is manufactured. It used for making music wire that has a hard dawn of ASTM A 277 and tempering of oil is ASTM A229 and the carbon value is ASTM A 230.

- High temperature alloy spring- As per the nominal analysis Ni is 26 % CR is 15% and Fe is 53%. The minimum tensile strength is 160 to 200 and modulus strength E is 29 percentage of the design stress is 35%.

- Alloy steel wire springs- As per the nominal analysis the chrome vanadium the ASTM is 231, C is48- .53%, the cr is 80- 1.10 % and Vis 15%. The minimum tensile strength is 190 to 300 and the modulus of the elasticity E is 30

- Stainless steel wire springs- As the nominal analysis of the Spring maker stainless steel wire springs is Cr- 17 and 19% Ni is 8 to 10%. The minimum tensile strength is 125 to 325, the modulus of elasticity E is 28. According to the spring manufacturing company it is the best material that you can put in use.

- Non ferrous wire springs- as per the nominal analysis Cu is 94 to 96 % and the minimum tensile strength is 105 to 145.